Moldex3D Optics analyzes various optical components, such as birefringence, retardation, and polarization. Integrated with CODE V optical design software, it simulates the non-uniform refractive index more precisely for high-quality lens production. Injection-molded optical parts, widely used in 3D applications, have become smaller and lighter. The flow-induced anisotropy would be more severe in smaller filling spaces. This results in key optical issues that cause a bottleneck in manufacturing injection-molded optical components.

Moldex3D Optics analyzes various optical components, such as birefringence, retardation, and polarization. Integrated with CODE V optical design software, it simulates the non-uniform refractive index more precisely for high-quality lens production. Injection-molded optical parts, widely used in 3D applications, have become smaller and lighter. The flow-induced anisotropy would be more severe in smaller filling spaces. This results in key optical issues that cause a bottleneck in manufacturing injection-molded optical components.

By relying on three-dimensional filling and viscoelastic analyses, Moldex3D Optics precisely predicts birefringence performance for flow-induced and thermally-induced parts. It optimizes processing factors, including part geometry, runner design, gate design, and filling speed, that affect important optical properties.

This software product also brings advanced optical solutions to help you analyze the manufacturing feasibility of part designs. In addition, it exports the deformed shape and refractive distributions into CODE V for part verification and optimization. This feature addresses the issues you encounter when ideal product designs go through real production.

Capabilities

- Predicts flow-induced birefringence in the filling, packing, and cooling processes

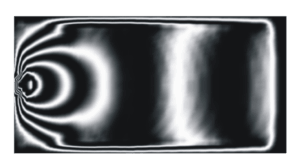

- Predicts flow-induced retardation, fringed orders, and fringed patterns

- Predicts thermally-induced birefringence, retardation, fringed orders, and fringed patterns

- Predicts refractive distributions

Results

- Three-dimensional filling analysis and viscoelastic analysis application

- Dedicated function for distinguishing the birefringence performance of flow-induced and thermally-induced parts

- Photoelasticity analysis application to analyze retardation, fringed orders, and fringed patterns

- CODE V integration to provide advanced simulations of deformation and refractive index

-

Request a quote for our plastics engineering services or contact us for additional information