|

Mold Filling Analysis & Other Plastic Manufacturing Solutions

Receive high-quality products and optimize your process with our reliable solutions. EPS FloTek, LLC is a worldwide leader in plastics engineering services, covering critical stages of the manufacturing process. Our comprehensive mold analysis services include filling, packing, and cooling to produce top-quality products that meet our clients’ requirements. We evaluate and optimize your manufacturing processes, enhancing efficiency and reducing production costs.

|

|

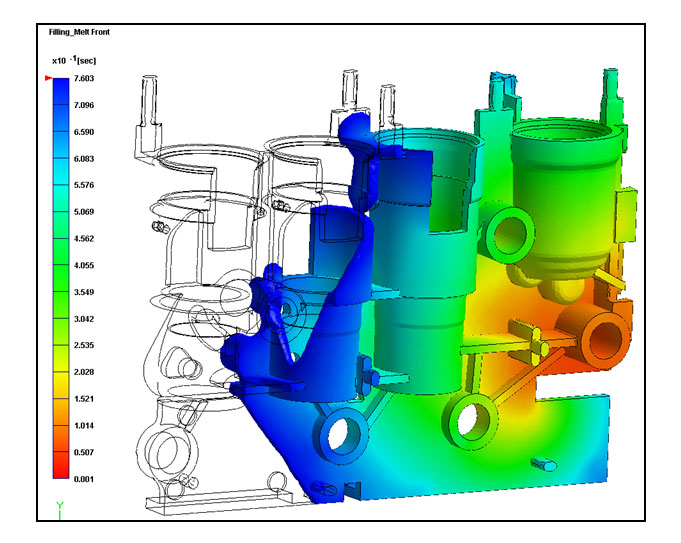

Mold Filling Analysis

The initial stage of plastics manufacturing is the Mold Filling Analysis, which is vital in determining the overall quality of the finished products. During this stage, we examine the conditions that occur during the initial flow of plastic material into the cavity. Our team reviews the balance and size of the runner, gate number, size, and location to address issues on time. Additionally, our team completes the following tasks:

- Optimizing Part Design

- Identifying Weld Line Locations

- Identifying Gas Trap Locations

- Reducing Pressure and Press Size

- Identifying Shear Stress Levels

- Clamping Force and Shot Weights

- Optimizing Processing Work

Mold Packing Analysis

The initial stage of plastics manufacturing is the Mold Filling Analysis, which is vital in determining the overall quality of the finished products. During this stage, we examine the conditions that occur during the initial flow of plastic material into the cavity. Our team reviews the balance and size of the runner, gate number, size, and location to address issues on time. Additionally, our team completes the following tasks:

- Optimizing Part Design

- Identifying Weld Line Locations

- Identifying Gas Trap Locations

- Reducing Pressure and Press Size

- Identifying Volumetric Shrinkage

- Clamping Force and Shot Weights

- Optimizing Processing Work

|

|

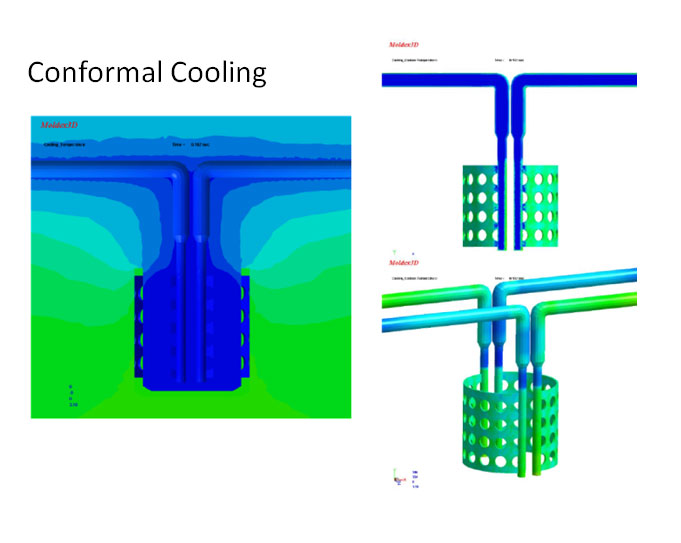

Mold Cooling Analysis

Mold Cooling Analysis is the final stage of the plastics manufacturing process, and it determines the quality and characteristics of the product. This service evaluates channel design, flow conditions, water temperature, and mold steel conductivity. The cooling stage is a reliable solution that ensures the final quality of the products by completing the following tasks:

- Reducing Cycle Time

- Eliminating Hot Spots in Tools

- Balancing and Reducing Flow Rates

- Balancing Temperature Rise

- Maximizing Channel Efficiency

- Identifying Nonturbulent Flow

- Identifying Channels to Circuit

- Using Conformal Cooling to Get Exact Shapes