Capabilities

- Evaluates the flow front pattern to help in part design and gate placement

- Predicts the penetration of the core material and skin breakthrough point

- Determines the best injection pressure and clamping force for proper molding machine selection

- Optimizes the switch point from skin injection to core injection

- Provides skin thickness distribution for advanced structural analyses

- Detects potential defective locations with high temperature and stress

- Estimates shrinkage and warpage concerning the interaction between skin and core materials for spec requirement

The Purpose of Co-Injection’s Molding Simulations

The co-injection molding process produces a plastic part with a skin and core laminated structure. The skin material is injected into the mold, followed by the core material. Next, the machine injects skin material again to encapsulate the core. This means that a product can be made with your desired appearance on the outer skin material.

Co-injection molding is widely used to enable regrind and reprocessed materials as the second-shot core material while bringing environmental benefits and reducing costs. The process also improves the strength and performance of high-impact plastics when used as core materials.

However, this process comes with several challenges. First, building a co-injection machine requires a hot runner system, control valve gates, and two barrels. These components cost more than a traditional injection molding machine. An even bigger problem is determining the optimal ratio of skin material to core material and track interface shape. There is also the matter of distributing individual components at any time and location in a cavity, which is critical for mechanical properties.

Co-Injection provides powerful modeling solutions that help you gain insight into critical characteristics of the process, such as material interface and distribution. It also optimizes your plastic manufacturing processes and lets you save on development costs.

Co-Injection offers modeling solutions to estimate shrinkage and warpage during the interaction between skin and core materials. It helps detect potential defective locations with high temperatures and stress. You also gain insight into critical characteristics of the process, including material interface and distribution.

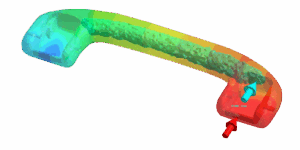

Co-Injection offers modeling solutions to estimate shrinkage and warpage during the interaction between skin and core materials. It helps detect potential defective locations with high temperatures and stress. You also gain insight into critical characteristics of the process, including material interface and distribution. Gas-Assisted Injection Molding (GAIM) visualizes 3D flow behaviors when gas is injected into the cavity through the melt entrance or specific gas entrances. This software product predicts fingering effects and other gas injection molding issues to help you investigate the real production process and increase manufacturability.

Gas-Assisted Injection Molding (GAIM) visualizes 3D flow behaviors when gas is injected into the cavity through the melt entrance or specific gas entrances. This software product predicts fingering effects and other gas injection molding issues to help you investigate the real production process and increase manufacturability.