Advanced Hot Runner Analysis

Bumpers, automotive instrument panels, LCD/TV panels, and other plastic injection molded products use hot runner molds. Aside from bringing material and energy cost savings, these solutions shorten cycle times for eliminated runners. However, hot runner systems are complex and encounter elaborate temperature control challenges and the risk of thermal degradation of plastic materials.

Advanced Hot Runner is the perfect solution to these problems. This software product provides simulation tools for designers and engineers to obtain mechanisms and critical information about hot runner molding. It lets you investigate the involved processes, detect potential defects, and optimize your designs. With Advanced Hot Runner, you can develop high-quality plastic products at low costs so you can succeed in a globally competitive market.

Capabilities

- Simulates hot runner systems and visualizes temperature distribution over time in the runners and mold base

- Validates hot runner systems and their subcomponents, including heating coils, manifolds, and hot nozzles

- Investigates hot runner molding processes and their characters, including injection pressure and clamping force

- Detects hot runner system defects, including welding lines and warpage

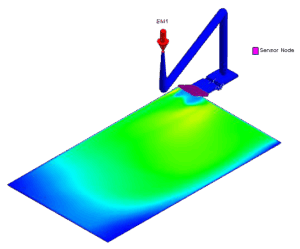

Injection Compression Analysis

This software product helps you simulate the injection compression molding process applied to thin and flat products, including light guide plates or CDs. It also simulates and visualizes the effects of key process conditions, such as delay time and compression gap, on cavity pressure and volume shrinkage distributions.

This software product helps you simulate the injection compression molding process applied to thin and flat products, including light guide plates or CDs. It also simulates and visualizes the effects of key process conditions, such as delay time and compression gap, on cavity pressure and volume shrinkage distributions.

In addition, Injection Compression lets you examine compression behaviors occurring during the filling or packing phases. Use its built-in control interface to inject plastic melt sequentially or simultaneously in the molding compression phase.

Our software product also enables you to adjust different compression conditions to meet real processing parameters. Its pressure and volumetric shrinkage performance analyses help you evaluate the best molding material and processing conditions for better manufacturability.

Capabilities

- Reduces injection pressure, molecular orientation, and warpage

- Distributes uniform pressure and volumetric shrinkage

- Avoids overpacking and material shear

- Improves venting and degree of reproduction

- Reduces cycle time

Results

- Complete injection compression molding simulations, including filling, packing, cooling, and warpage

- Easily adjustable key processing conditions, including compression gap or delay time in the Process Wizard

- Internal physical field visualization for velocity vector movements, pressure distribution variation in the cavity, sprue pressure, and clamping force feature

- Support for residual stress calculation and parallel processing to speed up calculation time

-

Request a quote for our plastics engineering services or contact us for additional information